Feb 1,2020

Feb 1,2020

High energy dairy feed having fats and oils has a high risk of feed oxidation which may lead to degradation of nutrients and development of rancidity. This leads to low energy, low nutrient and less palatable feed resulting into poor health, loss of production, reproductive inefficiency and loss of profit.

Auto-oxidation of feed is a spontaneous reaction of atmospheric oxygen with fatty acids, which manifest in the form of off flavors in feed. Oxidation is an irreversible reaction affecting the quality of nutrients present in animal feed and raw materials.

Autoxidation is a permanent danger at all stages, ranging from storage of raw materials and mixing for feed preparation. This risk is further increased when feed is subjected to high temperature and pressure.

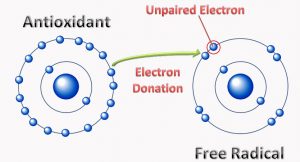

Oxidation leads to the formation of free radicals that destroy fat soluble vitamins like A, D,E and amino acids, causing loss of essential nutrients as well as lowering immune-competence.

Oxidative end products react aggressively with live tissues and disrupt cellular integrity. Pathogenic E.coli thrive on the damaged gut membrane and reduce feed efficiency whilst causing disease.

Oxidation must be controlled to protect the feed quality and nutrient losses and maintain optimum immune response.

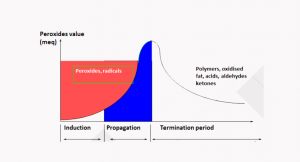

There are 3 phases in oxidation: Initiation or induction phase, propagation phase and termination phase. It is important to control the oxidation reaction right in the beginning itself as this is more easily achieved and more effective.

• Low availability of nutrients due to destruction of fat, fat soluble vitamins and amino acids

• Reduction in feed intake due to decrease in feed palatability

• Harmful effect on vital organs due to creation of toxic metabolites

• Decrease in milk production

• Decreased reproductive performance

• Negative influence on overall health and immunity

• It should be highly effective in preserving fats, vitamins and other nutrients in feed and prevent oxidative destruction

• It must be non-toxic

• It should be effective at low concentrations

• It should be cost effective

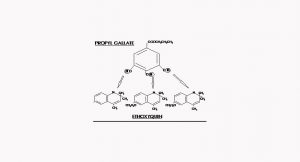

Based on the efficacy, stability and long term activity, it has been proven that a combination of Ethoxyquin, Propyl gallate and Citric acid is an ideal solution as a feed antioxidant. Ethoxyquin and Propyl gallate have a synergistic activity whereas Citric acid plays a critical role by chelating catalysts of oxidation reaction.

Ethoxyquin: It blocks oxidation by donating hydrogen ions to free and peroxy radicals formed during the onset and propagation stages.

Propyl Gallate: It restores and potentiates ethoxyquin activity up to 3 times by donating hydrogen ions from its 3 active sites to oxidized (spent) ethoxyquin molecules. In this way, it ensures that Ethoxyquin’s antioxidant activity is regenerated up to three times.

Citric Acid: It interferes with the initiation phase of the oxidation process through its metal chelating properties.

This formulation has proven and high level of antioxidant activity. Synergy between ethoxyquin and propyl gallate ensures longer and better protection. Overall, this is a highly effective combination and economical too.

Dairy feed formulations are nowadays rich in fat content. Feed manufacturers also add a vitamin premix which has fat soluble vitamins. The trend of adding amino acids and pigments is also getting popular. All these items are prone to autoxidation in feed which leads to loss of their nutritive value and defeats to a great extent the purpose of adding these components to the feed.

Dairy nutritionists recommend that an effective antioxidant is a must for a quality feed. It not only prevents oxidation but preserves nutritive value leading to superior performance.