Feb 1,2020

Feb 1,2020

Poultry industry is one of the fastest growing sectors in India today. Though the growth rate is high, the poultry industry regularly faces different types of challenges. Out of all the challenges, ammonia emission is one of the major ones the industry is facing, especially in the winter season. Ammonia is a colourless gas produced by the microbial decomposition of organic nitrogen compounds found in the manure. It is highly soluble in water and very toxic. It has a direct negative effect on the birds and farm workers.

There are several ways to control ammonia in the farm that includes ventilation, dietary management, litter management, feed additives etc. All these methods have some merits and demerits. Though ventilation is one of the most economical methods to control ammonia, its limitation is that it is completely dependent upon the external environmental conditions. Good sunlight with proper airflow makes it more effective. In winter season, when farms are completely covered with curtains this method is not effective. Similarly, in dietary management, specialists are required to reformulate the nutrient content in the feed on a regular basis.

To overcome these limitations and to control ammonia, one of the convenient and safe methods is the use of Yucca extracts as a feed additive. Yucca extract is obtained from the Yucca schidigera plant. This plant contains some active components like saponins and glycocomponents. Saponin helps to increase the permeability of the intestinal wall, thus allowing better nutrient absorption of the feed. Glycocomponents helps bind and neutralize ammonia. Yucca extract is very effective in binding of ammonia but most important point to be considered is its potency and therefore the required inclusion level to neutralize ammonia. The potency of any Yucca Extract is measured by its B50 value.

Ammonia accumulation in poultry sheds is a common challenge especially during winter season because of limited ventilation. Ammonia accumulation can also occur due to the usage of old litter for a long period.

Ammonia is a highly irritating, colourless gas having a sharp pungent odour. It is produced by the breakdown of uric acid present in the manure by bacteria. Temperature and moisture act as catalysts in this process. Ammonia is harmful both for birds and humans.

High level of ammonia is found to depress feed consumption, body weight gain, onset of sexual maturity and egg production.

Petkov (1966) has reported as much as 9% drop in egg production upon two-month exposure to high NH3 levels.

Birds show watery eyes, closed eyelids and rubbing of eyes with wings due to irritating nature of ammonia.

Due to high ammonia levels, egg white also starts deteriorating and there is discolouration of egg yolk which reduces the market value of the egg.

Birds exposed to higher ammonia levels developkerato conjunctivitis, air sacculitis, and show reduced respiratory rate and increased susceptibility to coccidiosis and various respiratory diseases due to damaged ciliary and epithelial lining of the respiratory tract.

Poor carcass quality in terms of increased breast blisters has been reported in broilers.

Ammonia is a potent immune- suppressant, and therefore, lesser the quantity liberated within the system of bird or animal, the better the health and healthier the environment.

There are various approaches available to control ammonia. Dietary treatment seems to be most logical in terms of efficacy and convenience. Any dietary ammonia binder should have the following properties:

• It should inhibit Urease enzyme

• It should bind preformed ammonia

• It should be effective in the gut as well as in the litter

Biopowder is a 100% natural and organic product, produced by the milling, pulverizing and standardization of stems of the Yucca schidigera plant.

Biopowder reduces and controls ammonia which affects the performance of birds. It improves productive parameters increasing the weight and increasing efficiency in production performance.

Biopowder has two active components, Saponins and Glycocomponents.

Saponins:

• Saponins do not allow the uric acid to get converted into ammonia, by binding with urease inside the cell.

• Saponins also work as a surfactant, and reduce the surface tension, thereby enhancing the absorption of nutrients

• Improve the microbial activity in the GIT

• Improve digestion

Glycocomponents:

• Glycocomponents bind directly with ammonia in the digestive tract, and remove it from the system, improving intestinal conditions

• They also continue to act in the environment by binding with ammonia and preventing its release into the air thereby maintaining a healthy environment within the shed

Nowadays, there are quite a few products available in the market based on Yucca. While selecting, one should ask for B50 value as it is a true indicator of the efficacy of product. It is also important that the extract should be specifically from the Yucca schidigera plant. There are many species of Yucca, but the extract from Yucca schidigera is considered to be the most ideal one in terms of efficacy and performance.

Several commercially available ammonia binders are either diluted or contain non-Yuccaschidigera components. These products can easily be identifiedby testing the B50 value of the product.

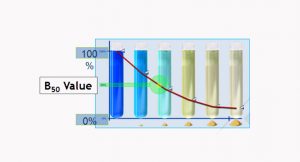

The B50 value indicates the milligrams of a Yucca extract necessary to reduce 50% of ammonia in aqueous solution.

In the B50 value test, it is the amount of Yucca extract required to bind 50% of ammonia produced by 0.2 milliliter of a 5 millimolar solution of ammonium sulphate. The result is interpreted by the change in the colour(blue to light blue) of the solution.Biopowderguarantees aB50 value of less than 5.0 mg. Lower the B50 value, better is the ammonia binding property.

Also lower the B50 value, lower is the product’s inclusion required to bind the same quantity of ammonia. Biopowder is generally recommended to be included into finished feeds at a standard inclusion of 100 grams/MT of feed and therefore the product offers the best ‘value proposition’ in terms of investment to return.

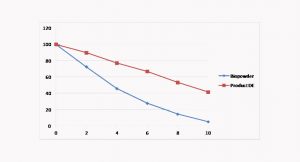

In a comparative study B50 value of Biopowder and a competing brand was conducted.

Results of study indicate that Biopowder has a B50 value of 3.6 mg whereas product DE has a value of 8.6 mg.

Which means that to bind with a quantity of Ammonia, if 3.6 mg of Biopowder is needed, then for same performance 8.6 mg of other brand is required which means that ammonia binding capacity of Biopowder is 2.4 times more as compared to another product. As per the comparison, Biopowder is far more cost effective and efficacious as compared to product DE.